- Services

-

Evaluating Your Printed ICC Profiling Target

- Information & FAQs

- Order / Pricing Printing Profile Targets

- Overview

- 1. Preparing for Profiling

- 2. Printing Your Target

- 3. Evaluating Your Target Specific Guides

- PC - Colour

- PC - Black & White

- Mac - Colour

- Mac - Black & White Using ICC Profiles

- How To Use ICC Profiles

Custom Printer Profiling

This is a page from our Custom ICC Profile Service Instructions.

Please see the panel to the right for a guide through these instructions.

Part 3

Evaluating Your Printed Target

These instructions are for evaluating the quality of your printed target for our Image Science profiling service.

Profiling is a process that requires you to follow the instructions very carefully. If you fail to do so precisely, the process won't work!

Now comes time to carefully check your target to make sure that it's all good and ready to send in to us.

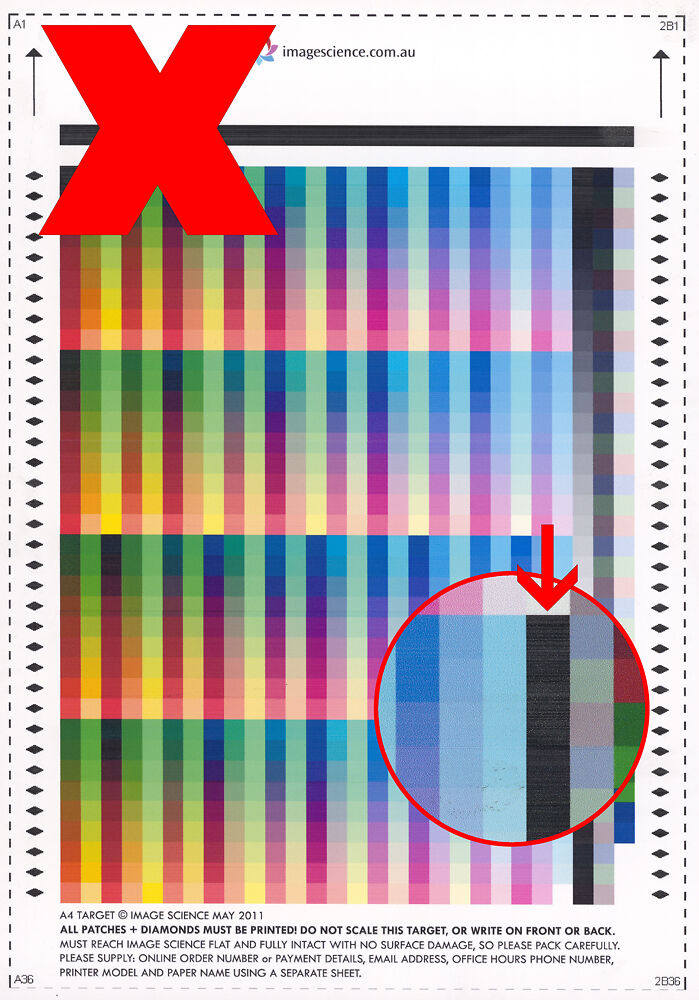

A Good Example

Firstly, for reference, the above is an example of how a well printed target should look.

In particular note the defined separation between each and every patch, particularly in the most saturated blues and greens.

Size

Measure your target.

- Is all of the target there?

- Is it the correct size?

Colour targets should be approximately 19.8 x 28.6cm measured at the dashed border.

B&W targets should be approximately 15.6 x 17.1 cm measured at the dashed border.

On Windows, ACPU has a bug that does sometimes scale the target slightly. If your target is within ~1cm of the above listed size in both dimensions then it should still read OK, so no need to re-print unless we let you know of an issue.

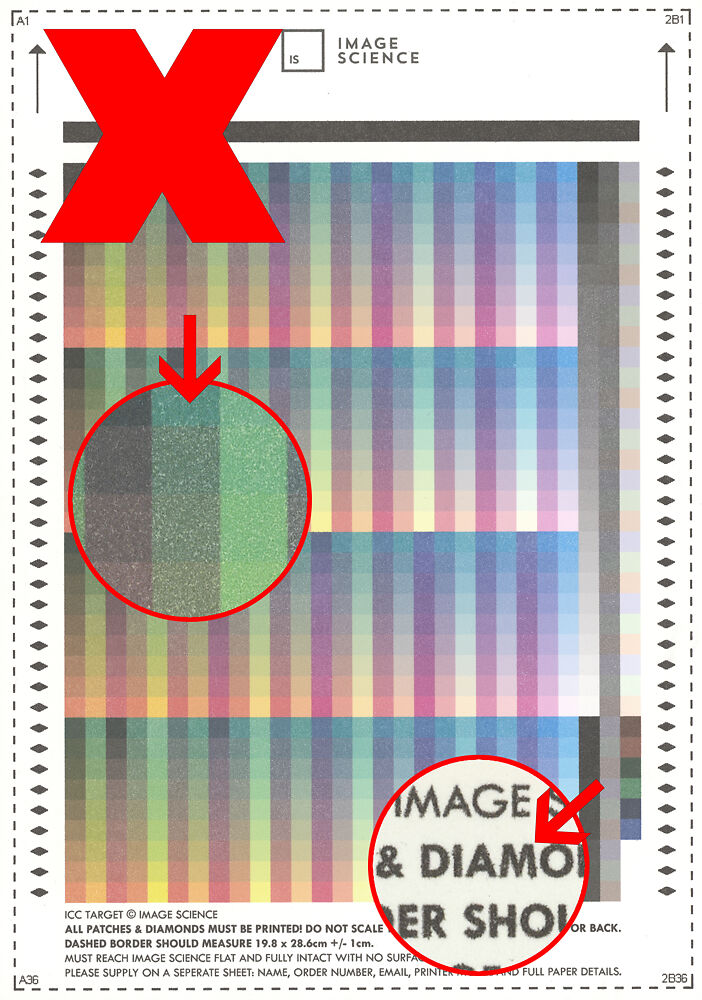

Gamut Compression

The number one most frequent issue we see with people's targets is that of gamut compression.

Take note of the above example, see how the most saturated end of the blues and greens all seem to blend into one - there is no separation between the patches. If you're seeing this in your target, then you've got some gamut compression coming from part of your process.

A target with gamut compression will not make a good profile (or sometimes even make one at all), if you're seeing this, it's important that you don't send it to us - better to sort your gamut compression issue out now and reprint your target rather than wasting the time and postage of sending it in for us to reject it.

The most common cause for gamut compression is driver issues, we see it most commonly on mac computers, and almost always due to an erroneous Airprint driver. Read more on this below.

Streaking & Blotching

The above is an example of target suffering from bad streaking - possibly due to the head scraping the page or incorrect settings.

Check:

- Are there any blotches or spots?

- Are there any streaks or faint lines?

If there are any quality issues, re-run your printer diagnostic checks, and then re-print the target.

Wrong Side Of Paper

The above is an example of target that was printed on the wrong (uncoated) side of the paper. Note the dull and unsaturated appearance of the colours, the presence of many tiny white dots and particularly note the overall unsharp nature of hard lines and the ink bleeding present in the text for example.

- Make sure you are printing on the correct (coated) side of the paper

We have an article about determining the printable side of cotton rags below.

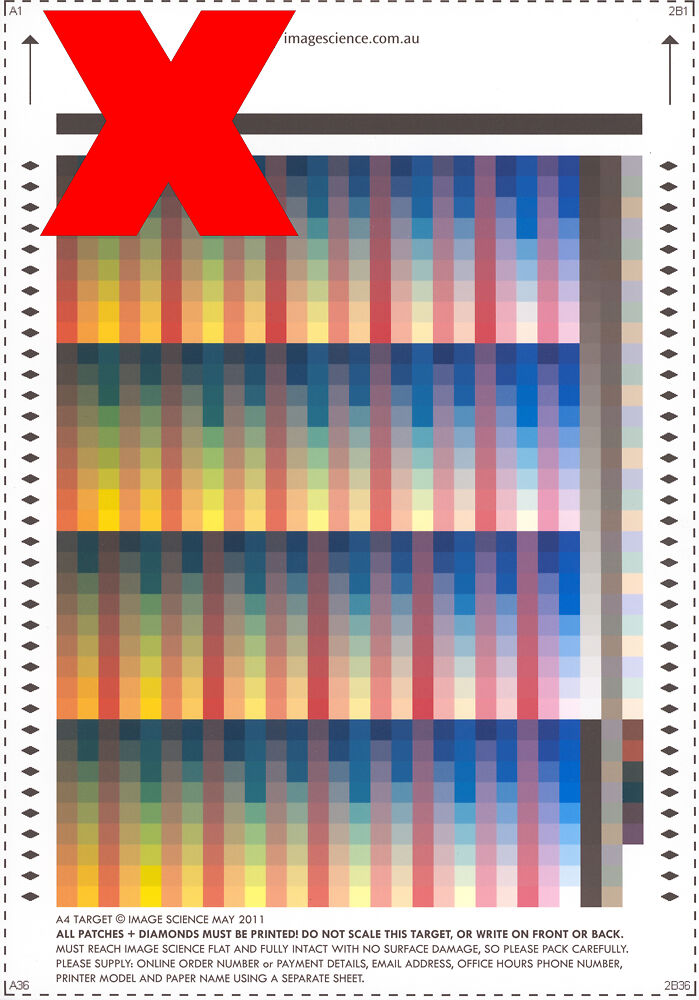

Colour Shifts

The above example shows some very bad (frankly atrocious) colour shifts that are indicative of some serious issues with either your printer itself, driver or software (plus extreme non-neutrality and gamut compression also to top it off).

- Check for any colour shifts that deviate from the good example further up the page

- Check for any other weird issues - if in doubt, send us an email

If you're getting results like this then something has gone seriously wrong along the way and should be looked into immediately - contact your place of purchase of your printer as a start point. Do not proceed further and certainly don't send us your profile.

Drying Time

Make sure to leave your target to dry for 24 hours as the colour can shift within the first few hours particularly.

Get It To Us

Mail it to us or drop it off if you're local.

If posting, make sure you send it to us flat packed in an envelope with card so it arrives to us flat and undamaged!

Remember, you must supply on a separate sheet your name, email address, printer model and full paper details.

Submit Order

Make sure you submit a corresponding online order of a custom profile to lodge your payment and contact details.

Using Your Profile

When you get your profile back, follow the instructions below to use it.